Custom Manufactured Signal Line Filters

Electromagnetic interference, or EMI, happens when undesired electrical signals affect electrical and electronic devices and equipment. EMI can be emitted from other nearby devices or from natural occurrences (e.g., lightning). Devices themselves also emit energy that can interfere with neighboring devices. It is important to control and mitigate both to protect signal transmission and equipment as well as device functionality.

Signal line filters are specialized passive devices that emit low current energy to protect systems and equipment against EMI and ensure that signals are complete and without distortion. Captor Corporation provides standard and built-to-print, custom signal line filters for use in a range of applications.

Learn more about signal line filters and how they are used.

The Purpose of a Signal Line Filter

Unwanted frequencies cause incomplete or distorted signal transmission. This interferes with the proper function of devices, circuits, and equipment. Some examples of vulnerable equipment include, but are not limited to cell phones, object detection sensors in vehicles, aircraft navigation systems, or medical equipment.

A signal line filter protects devices and equipment by filtering out undesired frequencies while allowing other acceptable ones to flow freely. They can suppress and divert frequencies in both directions: those coming into a device or circuit from external sources, or those flowing out from a device or circuit.

EMI line filters help ensure electromagnetic compatibility (EMC) between and among electronic components. As more and more electronics are introduced into industrial and consumer products, transportation systems, communication systems, and connected or “smart” equipment, the need for EMI filtering and EMC is greater than ever, and will only continue to grow.

Applications of Signal Line Filters

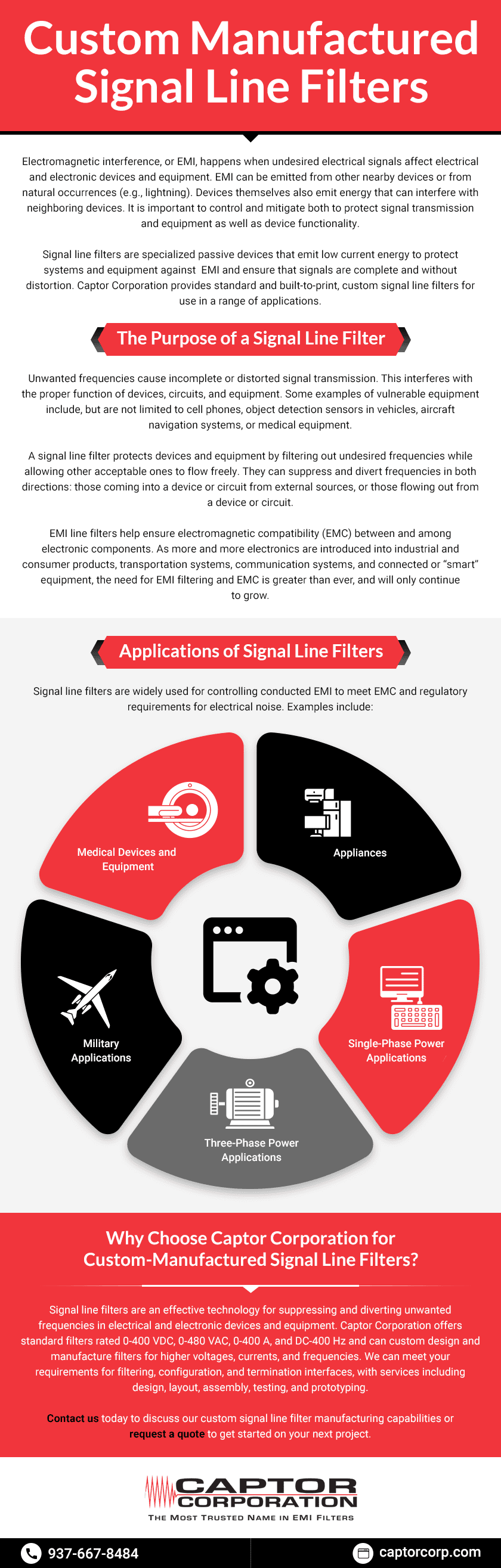

Signal line filters are widely used for controlling conducted EMI to meet EMC and regulatory requirements for electrical noise. Examples include:

- Appliances. Home appliances use EMI filters to reduce electromagnetic noise and protect internal electronic components from damage and malfunction.

- Single-Phase Power Applications. Small devices and equipment that require low electric power, such as that available in residential settings, can use single-phase filters. Examples include small appliances and motors, fitness equipment, computers, televisions, and lights.

- Three-Phase Power Applications. Industrial and commercial facilities often use three-phase power for equipment, motors, and large-scale systems that need higher electric power. Three-phase filters can suppress higher levels of noise.

- Military Applications. The military has strict standards for electrical signal noise, which are met with military-grade signal line filters. These can be used for mission-critical heavy-duty military and aerospace systems and to protect from high-altitude electromagnetic pulse (HEMP) threats.

- Medical Devices and Equipment. Sensitive electronic components are common in large and small medical devices and equipment. EMI filters protect them from damage and ensure proper operation in settings including protecting magnetic resonance imaging (MRI) rooms, operating rooms, and critical care settings from EMI generated by computers, lighting, and telecommunications equipment.

Why Choose Captor Corporation for Custom-Manufactured Signal Line Filters?

Signal line filters are an effective technology for suppressing and diverting unwanted frequencies in electrical and electronic devices and equipment. Captor Corporation offers standard filters rated 0-400 VDC, 0-480 VAC, 0-400 A, and DC-400 Hz and can custom design and manufacture filters for higher voltages, currents, and frequencies. We can meet your requirements for filtering, configuration, and termination interfaces, with services including design, layout, assembly, testing, and prototyping.

Contact us today to discuss our custom signal line filter manufacturing capabilities or request a quote to get started on your next project.